|

|

|||

|

|

| |

|

|

ECONOMICS :JATROPHA BIODIESEL

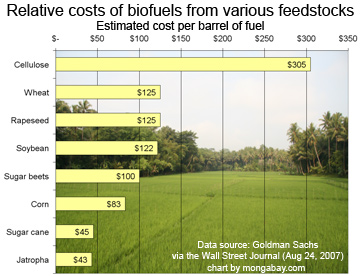

OVERVIEW The Biodiesel industry is still young and relatively small, so as it grows to a larger scale and when an infrastructure is developed, the costs of producing and marketing biodiesel may decline. New cost-saving technologies will likely be developed to help producers use energy more efficiently, increase conversion yields and convert cheaper feedstocks into high-quality biodiesel. However, in the longer term, the biggest challenge may be the ability of the feedstock supply to keep up with growing demand. The supply of soybeans, rapeseeds and other feedstocks available for biodiesel production will be limited by competition from other uses and land constraints. As such the key to the future of Biodiesel is finding inexpensive feed stocks that can be grown by farmers on marginal agricultural land, and Jatropha is one of many plants that hold a great deal of promise. Jatropha proves to be a promising Bio Fuel plantation and could emerge as a major alternative to Diesel thus reducing our dependence on Oil imports and saving the precious Foreign Exchange besides providing the much needed Energy Security. Jatropha oil displacing conventional fossil fuel makes the project fully eligible as a CDM project, i.e. recipient of CO2 credits.

COST BENEFITS SCENARIO Cost benefits scenario will depend on various factors such as seed yield, area of Production, its gestation period, and raw oil yield during various stages of bio-diesel production-plantation, extraction, and transesterification. An integrated Jatropha Biodiesel Project has three stages:

The combination of three stages of bio-diesel production and the role of each player in these stages have to be objectively defined as they can affect the economics of bio-diesel production Therefore, we have carried out Economic analysis considering all above three stages as separate entities Kindly visit relevant page for complete information For further enquiry kindly contact: H/P: +91 9829423333 |

© 2004- 2025 ABC-Advanced Biofuel center ,, All Rights Reserved |

Jatropha stacks up nicely compared with other feedstocks, as soybeans and rapeseed have a relatively low oil yield compared with Jatropha — 375 kilograms per hectare for soybeans in the United States (280 gallons per acre) and 1,000 kilograms per hectare of rapeseed in Europe (740 gallons per acre) to 3,000 kilograms per hectare of Jatropha (2,226 gallons per acre) in India. Good planning, quality planting material, standardized agronomy practices and good crop management could increase yields

Jatropha stacks up nicely compared with other feedstocks, as soybeans and rapeseed have a relatively low oil yield compared with Jatropha — 375 kilograms per hectare for soybeans in the United States (280 gallons per acre) and 1,000 kilograms per hectare of rapeseed in Europe (740 gallons per acre) to 3,000 kilograms per hectare of Jatropha (2,226 gallons per acre) in India. Good planning, quality planting material, standardized agronomy practices and good crop management could increase yields